Automatic Vertical Slitting & Rewinding Machine

This automatic vertical slitting & rewinding machine is an ideal choice for cutting, separating and slitting a variety of roll materials, such as BOPP, PET, CPP, CPE, PVC, as well as materials which are laminated with foil, film and/or paper. It can also edge the material based on producing requirements.

Technical Parameters

| Model | LFQ700B | LFQ1100B | LFQ1300B |

| Max.width of mother roll (mm) | 700 | 1100 | 1300m |

| Max. diameter of mother roll (mm) | ф600 | ф600 | ф600 |

| Width of final roll (mm) | 50~700 | 50~1100 | 50~1300 |

| Max. diameter of rewinding (mm) | ф450 | ф450 | ф450 |

| Inner diameter (mm) | 76 | 76 | 76 |

| Mechanical speed (m/min) | 220 | 220 | 220 |

| Slitting and rewinding speed (m/min) | 200 | 200 | 200 |

| Tolerance of EPC (mm) | ±0.5 | ±0.5 | ±0.5 |

| Power (kW) | 3 | 4 | 4 |

| Weight of machine (kg) | 1500 | 1800 | 2000 |

| Dimension (L×W×H, mm) | 1570×2100×1500 | 1570×2500×1500 | 1570×2700×1500 |

Details

- Unwinder

1. 5kg magnetic brake cooled by a seperate fan, this helps to prolong the life of the equipment, as well as its stability.

2. 76mm air shaft makes it easy to change rolls within 20 seconds.

3. Automatic tension controlling.

4. Setting tension parameters more accurately and with ease is possible.

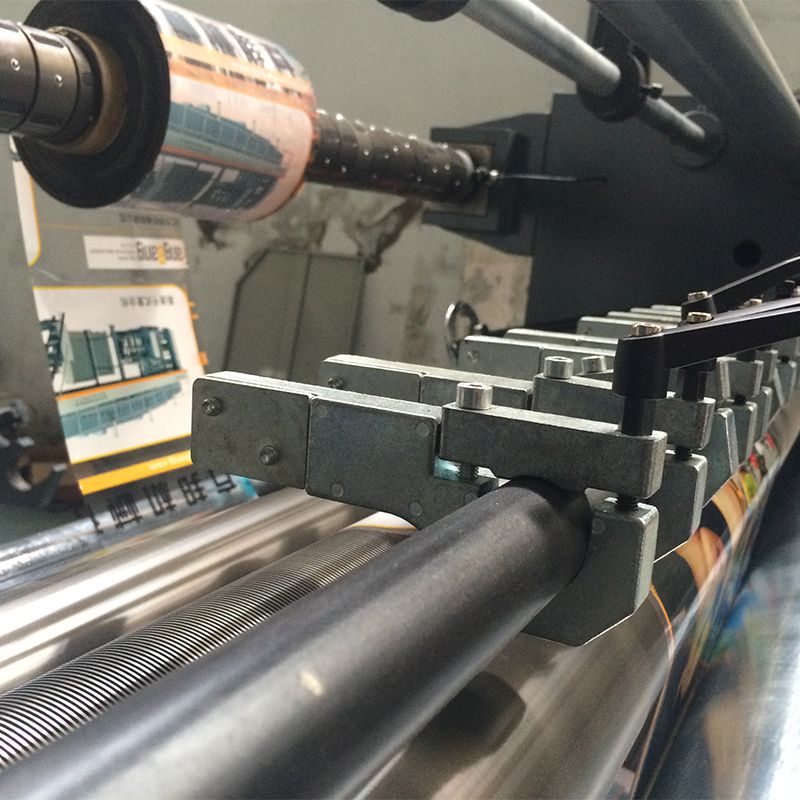

5. The screw-type EPC motor controller is capable of photocell tracking roll edge control - Machine Body

1. Motor: This motor boasts a 4kW output, is approved to the CE standard, and features an inverter controller for effective operation.

2. Slitting knife: simple to change and offer a straight cut.

3. Driving system: synchronous belt

Rubber conveyors are superior to chain conveyors for longer life and low noise operation,

4. Counting system: keep track of the length of our slitting process, alerting us when it is necessary to replace the rolls. - Rewinder

1. Air shaft: Two outlets designed to facilitate explosive air release are needed, one on each end to change rolls easily

2. magnetic clutch: automatic tension adjustment for rewinding rolls with a weight of 5kg

3. Shaft Turning: Cardan Axis is an ideal way to quickly and easily remove and replace rolls. - Controller Inverter: Eura inverters, made in Taiwan, are preferable to Kewo from China.

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch