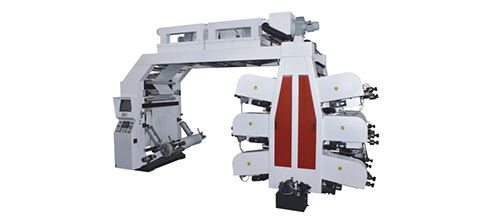

PP Blown Film Machine

The PP blown film machine is applicable in making high and low density polyethylene (HDPE, LDPE) which are widely used for packaging of food, garments, textile, daily necessities and industrial products.

Constructed of high-grade alloy steel and treated with precise finishing and nitrogen treatment, the cylinders and screw stems of the extruder of this PP blown film machine are endowed with superior hardness and exceptional corrosion-resistance.

Thanks to modern technology, the PP blown film extruder can be raised up to 3 meters in order to meet the requirements. Additionally, it boasts a bottom film blowing process, and the coiling unit with a torque motor in order to keep the tension consistent and make changing/rolling of the film easy.

Technical Parameters

| Model | SJ-55-FM600 | SJ-60-FM700 | SJ-65-FM800 |

| Screw diameter (mm) | 55 | 60 | 65 |

| Screw L/D ratio | L/D28:1 | L/D28:1 | L/D28:1 |

| Screw speed (r/min) | 10-100 | 10-100 | 10-100 |

| Power of main motor (kW) | 15 | 18.5 | 22 |

| Rotation mode of machine head | constantly revolve | constantly revolve | constantly revolve |

| Max. capacity (kg/h) | 32 | 38 | 50 |

| Max. folding width of film (mm) | 600 | 700 | 800 |

| Thickness of film (mm) | 0.01-0.10 | 0.01-0.10 | 0.01-0.10 |

| Total power (kW) | 22 | 28 | 36 |

| Weight (kg) | 2300 | 2900 | 3500 |

| Dimensions (L*W*H, mm) | 4800*2000*4000 | 4800*2000*4000 | 5000*2200*4200 |

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch