ABA Three Layer Blown Film Machine

In this ABA three layer blown film machine, bi-metal alloy steel which contains 15% Tungsten carbide makes the barrel and screw particularly robust. This hardness ensures that they have a longer life expectancy by no less than 5 years.

Taiwanese engineering is behind the design of the screw, particularly the feeding and mixing parts. These components have substantially increased the productivity of the machine and the quality of the film.

ABA design is a great way to reduce material costs and increase productivity, ultimately resulting in increased profits. Additionally, with this design we can mix up to 50% calcium carbonate in the B screw.

We use top-tier components, such as a Siemens main motor, an LS inverter, and an Omron temperature controller. These components ensure high quality and outstanding performance.

| Model | SJ-50/ABA800 | SJ-55/ABA1000 | SJ-60/ABA1200 |

| Screw diameter (mm) | 45/50 | 55/50 | 60/55 |

| Screw L/D ratio | 30:1 | 30:1 | 30:1 |

| Width of film (mm) | 200-800 | 250-1000 | 300-1200 |

| Thickness of film (mm) | 0.01-0.10 | 0.01-0.10 | 0.01-0.10 |

| Max. extrusion capacity (kg/h) | 100 | 120 | 150 |

| Power of cooling cylinder (kW) | 0.13*2 | 0.13*2 | 0.13*2 |

| Power of driving motor (kW) | 11/15 | 18.5/15 | 22/18.5 |

| Temperature control | 3/3 | 3/3 | 3/4 |

| Average power (kW) | 50 | 52 | 55 |

| Die size (mm) | 80/150 | 100/200 | 120/250 |

| Winding speed (m/min) | 10-80 | 10-80 | 10-80 |

| Power of take-up motor (kW) | 1.5 | 1.5 | 1.5 |

| Weight (kg) | 3000 | 3300 | 3500 |

| Cover dimension (m) | 4.2*3.3*4.5 | 4.4*3.5*6.5 | 4.6*3.6*6.5 |

- Screw

1. Material: 38 CrMoALA

2. Material elemental analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3. Hardness of tempering: HB260-290

4. Depth of nitriding treatment: 0.4-0.7 mm

5. Hardness of surface: HV900-1050

6. Roughness of surface: 0.32 Ra

7. Linearity of screw: 0.015 mm/m

8. Bimetal screw: designed with a layer of tungsten carbide applied to the thread.

9. Hardness of bimetal layer: HRC 58-62

10. Depth of bimetal layer: 2-3 mm

11. Bimetal layer elements: Fe, Ni, B, C, Cu, etc. - Main Motor (Siemens)

1. Speed: 1400 rpm

2. Motor power: 380V, 3-Phase, can be adjusted as needed.

3. Service life: more than 10 years. - Gearbox

1. Functions: reduces speed of transmission

2. Speed rate: 10:1

3. High strength hard gearbox boasting service life

4. Transferring requires lubrication oil.

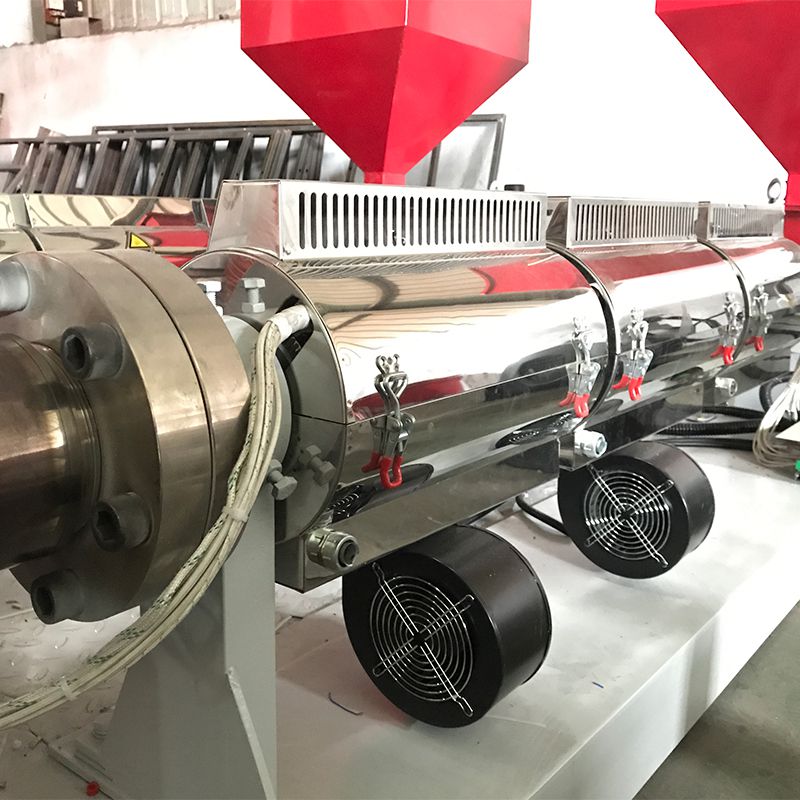

5. Low noise and longer service life - Main Extruder

1. A stainless steel cover can be used to improve the performance of the heater and reduce energy consumption.

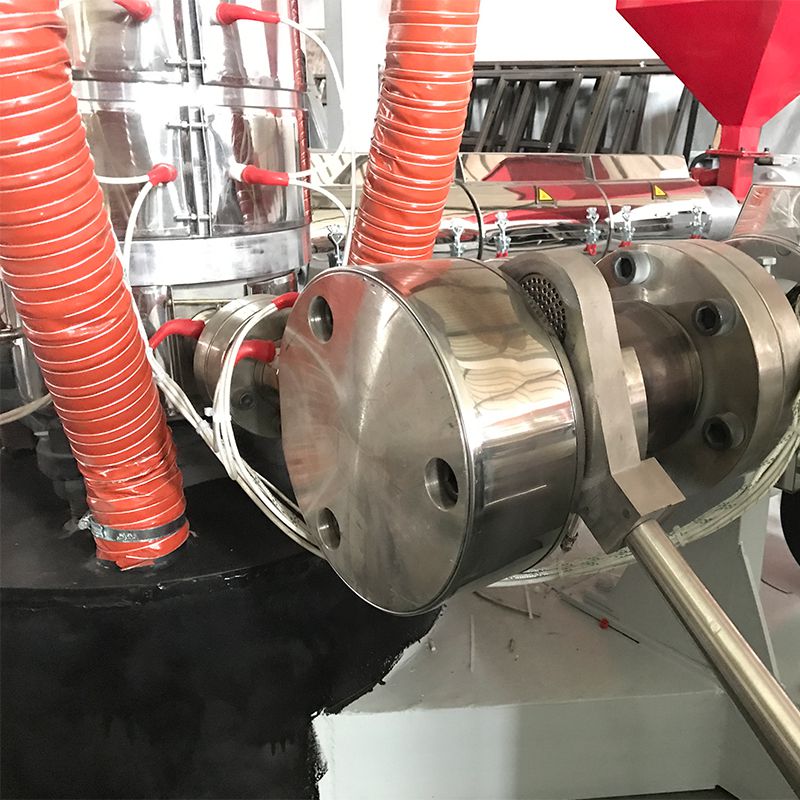

2. The stainless cover boasts a separate blower and a well-designed outlook. - Fix Die Head (Taiwan design)

1. Made from #45 steel, providing robust performance.

2. Surface treatment is employed to increase the transparency of films.

3. The size of die heads is larger than normal, resulting in increased efficiency and productivity. - Fast Screen Changer

1. Ensure that workers are employed efficiently

2. Minimize the risk of material leak

3. Easy to change the filters, saving time and human labor - Electric Parts

1. Omron temperature controller, LS inverter

2. Temperature control is precise within 3°C

3. Longer service life of more than 10 years - Single Rewinder

1. Automatic tension control allows for consistent speed to be maintained throughout the Traction process. This ensures the desired speed is achieved automatically, without manual input.

2. Using LG inverter to regulate motor speed, thus allowing for conserving energy consumption.