Single-layer Blown Film Machine

with Taiwan design extrusion screw and barrel

This Taiwan-design single-layer blown film machine is made with bimetal materials, heated and treated for 7 days, making it very resilient and long-lasting. With its Taiwan screw design, the machine parts are robust, optimally facilitating improved film quality and higher production rate. The single-layer blown film machine is suitable for blowing plastic films such as HDPE, LDPE, LLDPE, and biodegradable materials, and does not require a high factory setup.

Technical Parameters

| Model | TPH45 |

| Screw diameter (mm) | Ø45 |

| Max. width of film (mm) | 100-600 |

| Thickness of film (mm) | 0.008-0.10 |

| Capacity (kg/h) | 45 |

| Screw L/D ratio | 30:1 |

| Power of main motor (kW) | 11 |

| Power of traction main motor (kW) | 1.5 |

| Total power (kW) | 25 |

| Dimensions (L*W*H, m) | 4.0*1.5*4 |

| Weight (kg) | 2500 |

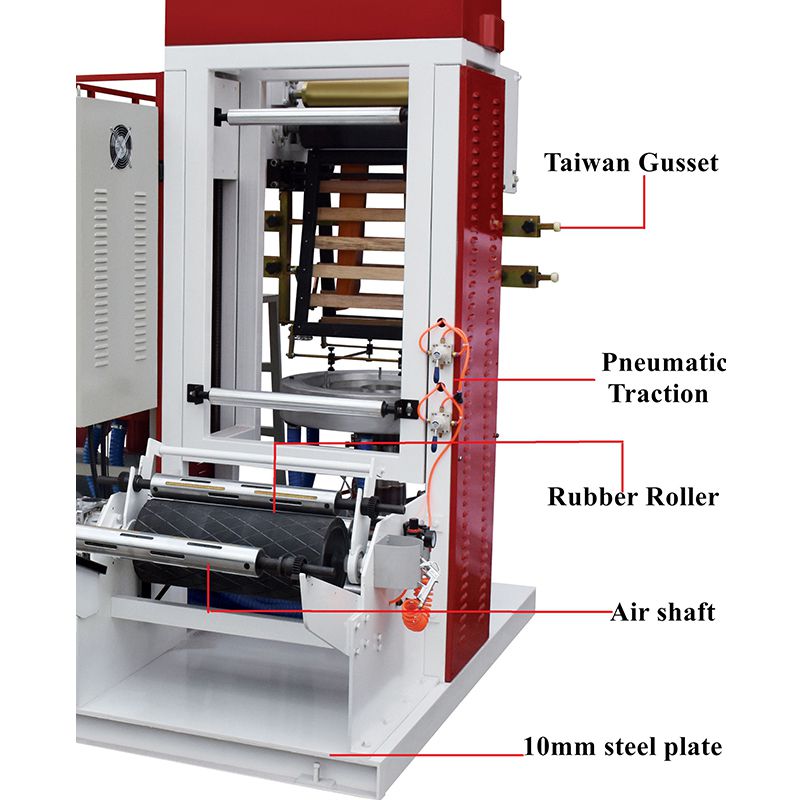

Main Components

- Screw (Taiwan Bimetal)

1. Material: 38 CrMoALA

2. Material elemental analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3. Hardness of tempering: HB260-290

4. Depth of nitriding treatment: 0.4-0.7 mm

5. Hardness of surface: HV900-1050

6. Roughness of surface: 0.32 Ra

7. Bimetal screw: designed with a layer of tungsten carbide applied to the thread

8. Hardness of bimetal layer: HRC 58-62

9. Depth of bimetal layer: 2-3 mm

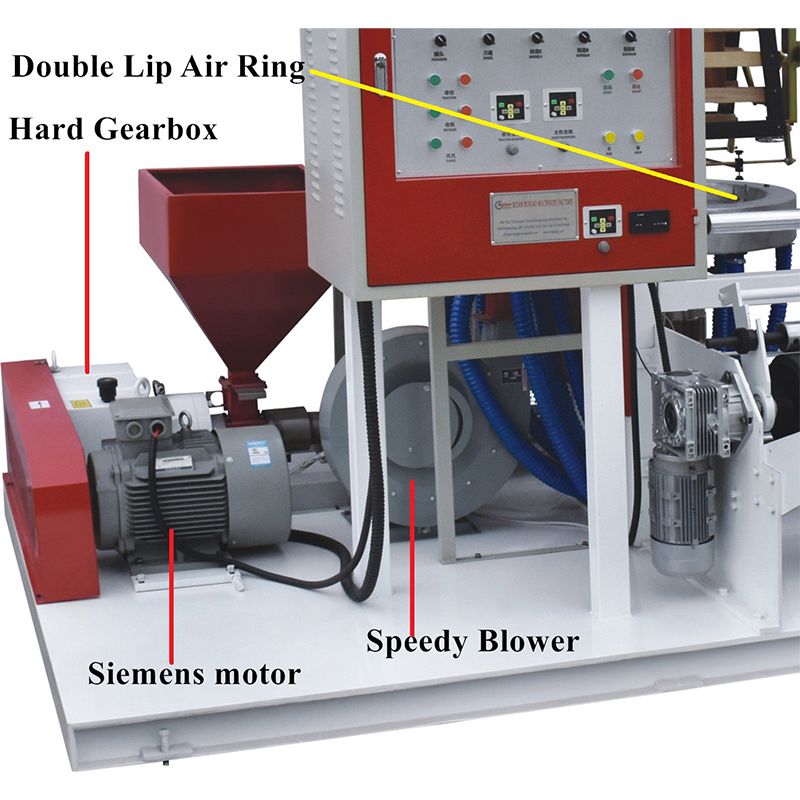

10. Bimetal layer elements: Fe, Ni, B, C, Cu, etc. - Main Motor (Siemens)

1. Speed: 1400 rpm

2. Motor power: 380V, 3-Phase, can be adjusted as needed

3. Service life: more than 10 years - Gearbox

1. Functions: reduces speed of transmission

2. Speed rate: 10:1

3. High strength hard gearbox boasting service life

4. Transferring requires lubrication oil.

5. Low noise and longer service life - Heater

1. Ceramic heater heats up faster than stainless-steel alternatives

2. Its lifespan is no less than 5 years

3. It can better retain heat, resulting in lower power consumption

4. Made from high-quality ceramic and heating wire. - High Speed Die Head (Taiwan design)

1. #45 steel and 3-day hot treatment, guaranteeing the most accurate thickness of the film

2. Made from Taiwan Processing Center ensures that the exact distance is calculated accurately - Taiwan Double Lip Air Ring Cooling the film at a faster rate can enhance its quality

- Controller Box and LG Inverter

1. LG inverter to adjusting the speed of all motors in order to reduce power consumption, as well as protect the proper functioning of the motors

2. LG inverter technology enables appliances to run for 10 years or more - Traction Part

1. Gusset part adopts Taiwan design, easy to adjust

2. Wooden gusset with angle, instead of flat type - Single Rewinder

1. Tension control to make sure the film will be tighter

2. After the roll has been changed, the air shaft can be adjusted to operate automatically, making it easy to use

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch