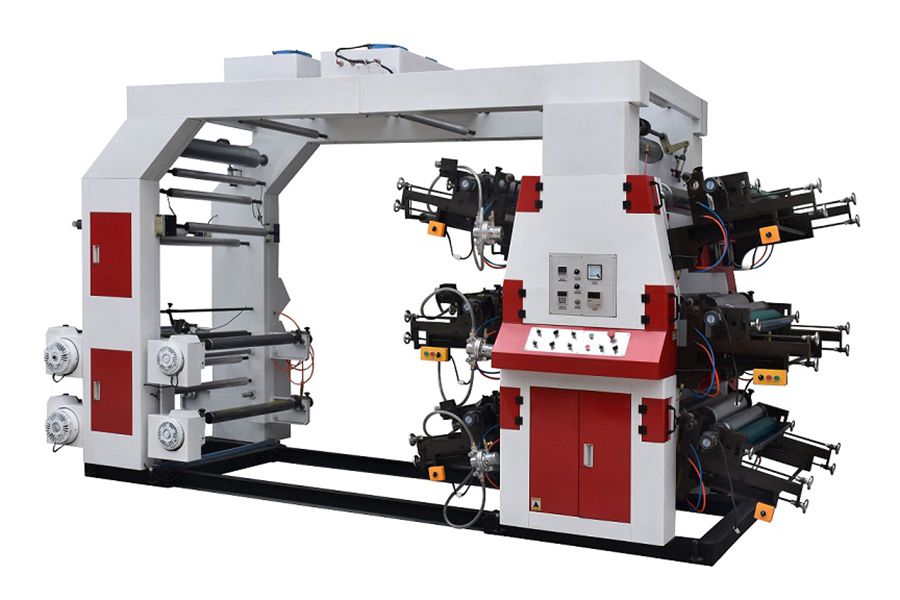

High Speed 4/6 Color Flexographic Printing Machine

CI Flexo Press for Film Printing

High Speed Six-Color Flexographic Printing Machine

Technical Parameters

| Model | YT-6600 | YT-6800 | YT-61000 | YT-61200 |

| Max.width of printing material (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing width (mm) | 560 | 760 | 960 | 1160 |

| Product length (mm) | 191-1200 | 191-1200 | 191-1200 | 191-1200 |

| Max. diameter of roll material (mm) | Ø450 | Ø450 | Ø450 | Ø450 |

| Printing speed (m/min) | 70 | 70 | 70 | 70 |

| Accuracy (mm) | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Total power (kW) | 10 | 10 | 11 | 11 |

| Weight (kg) | 3500 | 4200 | 5000 | 5500 |

| Dimensions(mm) | 5500×1660×2950 | 5500×1860×2950 | 5500×2060×2950 | 5500×2260×2950 |

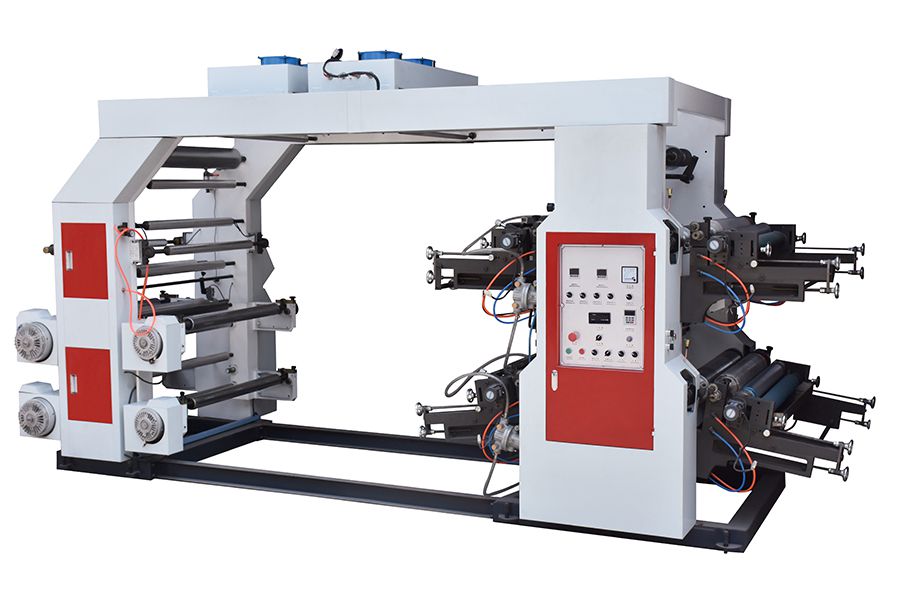

Four-Color Flexography Printing Machine

Technical Parameters

| Model | YT-4600 | YT-4800 | YT-41000 | YT-41200 |

| Max. effective printing width (mm) | 560 | 760 | 960 | 1160 |

| Max. web width (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing speed (m.min) | 70 | 70 | 70 | 70 |

| Max. mechanical speed (m/min) | 80 | 80 | 80 | 80 |

| Max. diameter of roll material (mm) | ф450 | ф450 | ф450 | ф450 |

| Roll material inner diameter (mm) | ф76 | ф76 | ф76 | ф76 |

| Repeated length (mm) | 191-1200 | 191-1200 | 191-1200 | 191-1200 |

| Accuracy (mm) | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Power of heater (kW) | 8 | 9 | 10 | 12 |

| Total power (kW) | 11.5 | 15 | 18.5 | 22 |

| Weight (kg) | 3000 | 3500 | 4000 | 4500 |

| Dimensions(mm) | L4300×W1700× H2500 | L4300×W1900× H2500 | L4300×W2100× H2500 | L4300×W2300× H2500 |

Standard Unwinder and Rewinder

- Double unwinder & rewinder: Switching between rolls of material is an easy and time-saving task

- 5kg automatic tension brake

- Tension sensor

- Automatic tension controller

Automatically change the tension accordingly. - Air shaft: An air shaft with a diameter of 76mm is ideal for use on a rewinder or unwinder, providing an easy way to change rolls.

- EPC motor: high-precision motor to create highly consistent and even printed materials.

- EPC sensor: renowned for its superior quality in China, providing unbeatable accuracy.

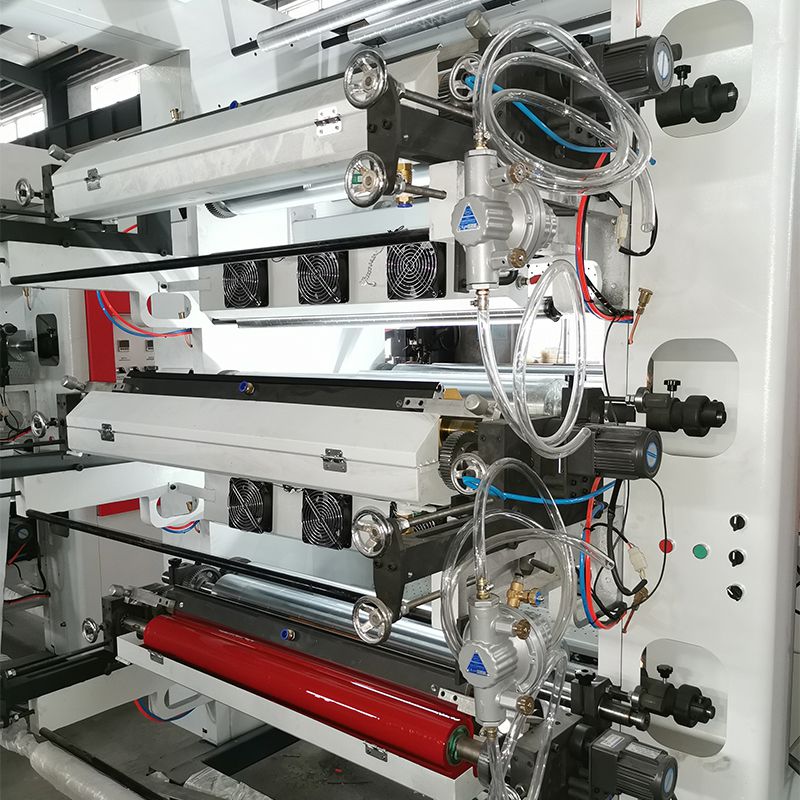

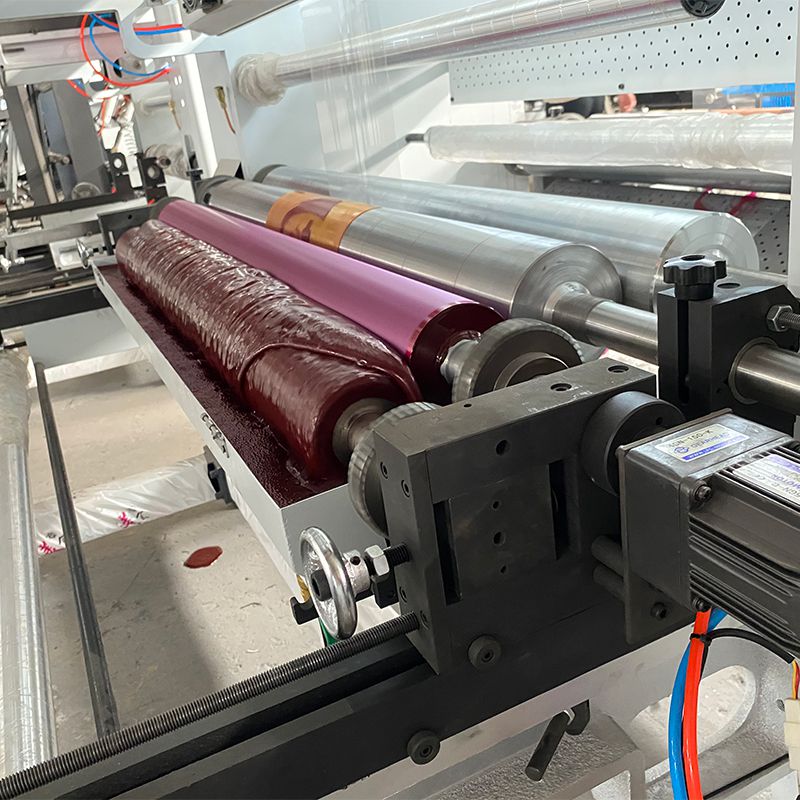

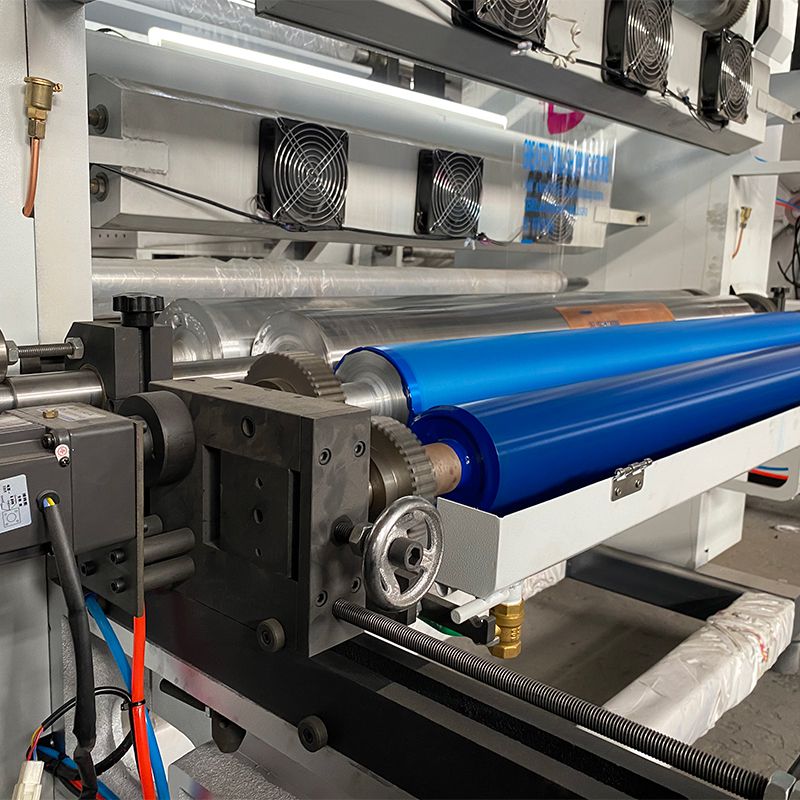

Printing System

- Doctor blade: metal doctor blades are utilized to ensure an even application of ink onto an anilox roller, delivering a smooth and consistent result.

- Anilox Roller: Anilox Rollers are crafted from steel and feature a maximum line screen of 320LPI with a hexagonal design for maximum ink carry. Designed specifically for printed images, Anilox Rollers provide optimal results for all types of printing.

- Separate motor for ink roller: A motor for ink roller is independently provided and will start automatically when the machine is not in use. This ensures that ink flow is maintained and no drying up of ink occurs.

- Adjust Bar: Robust steel adjust bar.

- Ink pump: Automatic ink pump frees human labour.

- Oil lubrication system: decreasing noise generated, as well as an increase in smooth and efficient operation.

- Hydraulic lifting system: provide far more stability than pneumatic counterparts

Transferring System

- Synchronous belt This precise printing has a resolution of 0.25mm and runs with significantly reduced noise levels.

- Helical gear This printer offers top-notch printing with its high-precision helical gearing providing exceptional quality results.

- NSK Bearing The renowned Best Brand in Japan is renowned for its long-term performance and endurance, providing users with more than 10 years of efficient and reliable use.

Drying System

- Separate heater

Used to dry up ink faster - The upper drying system has a hot and cold drying section, which enables it to operate at 70m/min while effectively drying the printing ink.

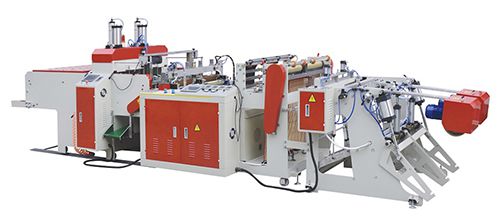

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch