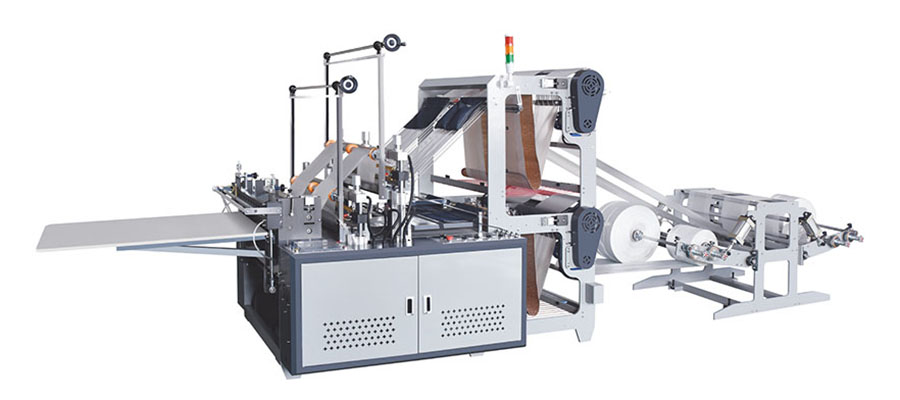

Automatic 4 Lines Biodegradable Bag Making Machine (New Design)

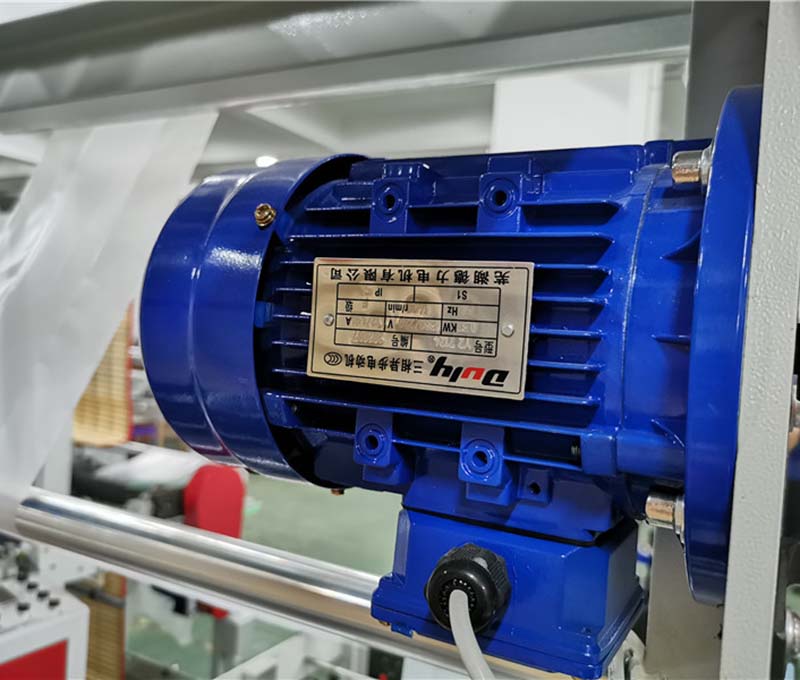

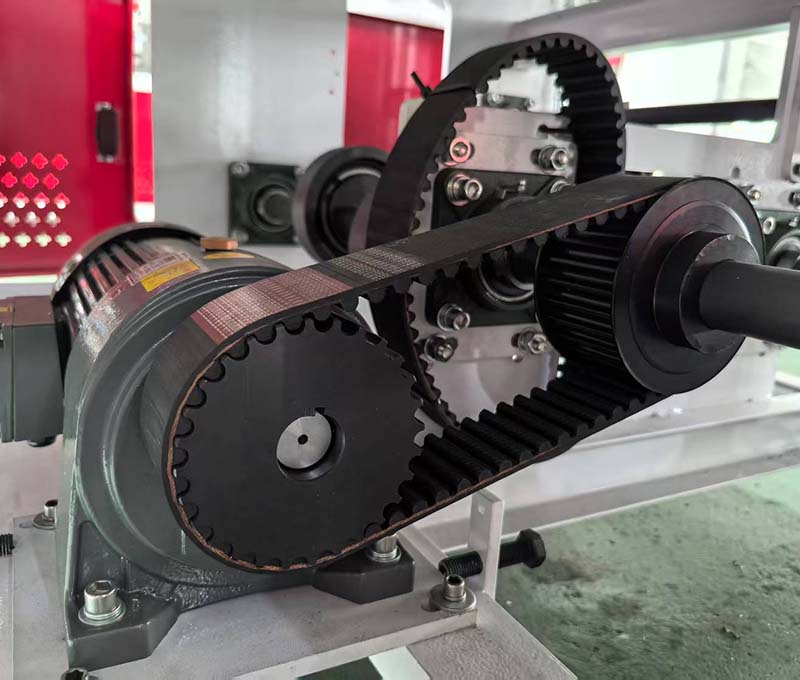

This biodegradable bag making machine is designed for producing vest bags and flat-opening bags made from eco-friendly materials. It features a Taiwan frequency conversion main motor that reduces energy consumption and allows smooth speed adjustment. The Taiwan-designed unwinder operates in perfect sync with the main machine for improved performance. Built with high-quality electrical components from trusted global brands, the machine ensures long-lasting reliability. Fully automatic operation reduces labor requirements and supports environmentally responsible production.

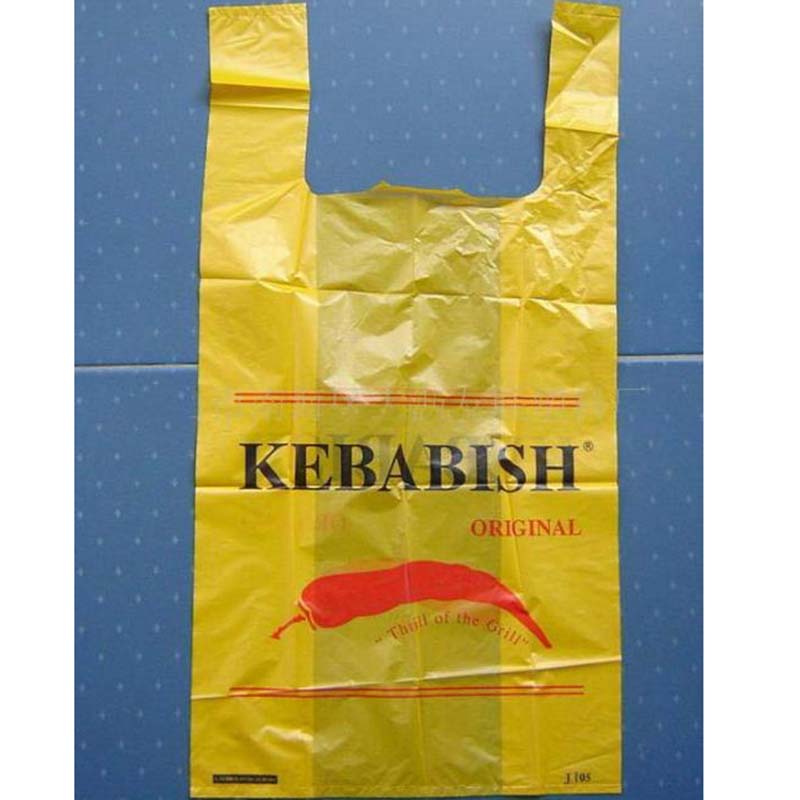

Bag Samples

Technical Parameters

| Model | TP-DLA800 |

TP-DLA1000 |

TP-DLA1200 |

| Sealing and cutting width (mm) | 750 x 2, 360 x 4 | 950 x 2, 460 x 4 | 1150 x 2, 560 x 4 |

| Sealing and cutting length (mm) | 1500 | 1500 | 1500 |

| Bag making speed (pcs/min) | 280 - 560 | 280 - 560 | 280 - 560 |

| Power of motor (kW) | 1.5 | 1.5 | 2.2 |

| Weight (kg) | 1500 | 1600 | 1700 |

| Dimension (L×W×H) (m) | 4.8 x 1.4 x 1.9 | 4.8 x 1.6 x 1.9 | 4.8 x 1.8 x 1.9 |

Details

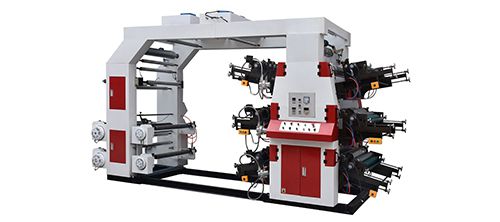

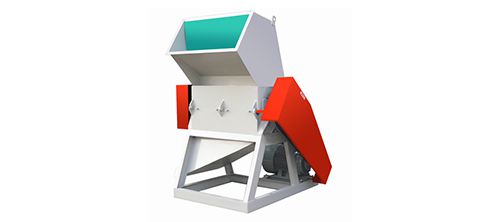

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch