Plastic Bag Making Line

The plastic bag production line consists of a film blowing machine, printing machine, and plastic bag making machine.

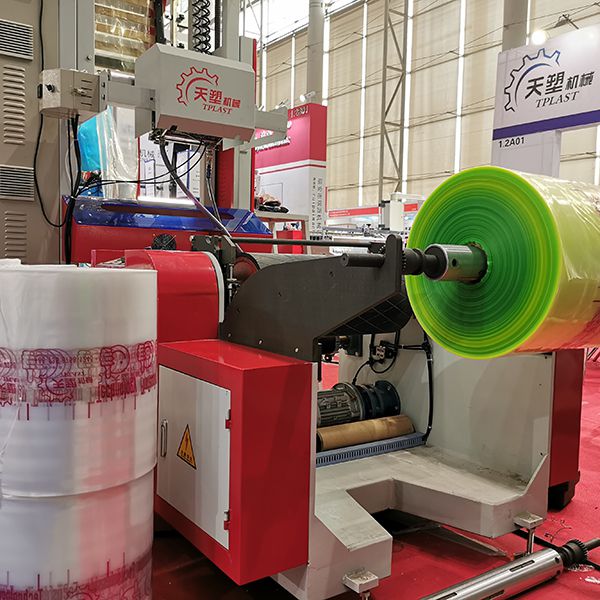

- The film blowing machine produces film rolls from either HDPE or LDPE materials. In order to select the most appropriate machine for the task, the material to be used must first be determined. There is a wide array of film blowing machines, with some being ideal for shopping bags and others better suited for packing film. Consequently, it's important to consider your specific film usage requirements.

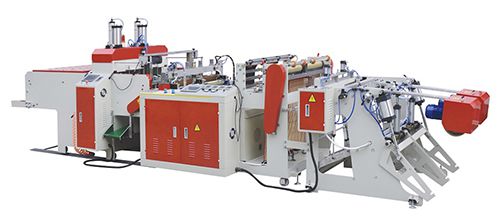

- The bag making machine is capable of creating a variety of types of bags such as shopping, garbage, and bread bags in a range of sizes from large to small. It is able to meet any desired specifications.

- The printing machine is capable of printing logos or pictures on bags, and there are 2, 4 and 6 color options to choose from based on the desired amount of colors. Generally, the 4 color printing machine is the most preferred when printing shopping bags. Before printing, it is important to pre-treat the film surface, or the ink can be easily lost.

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.