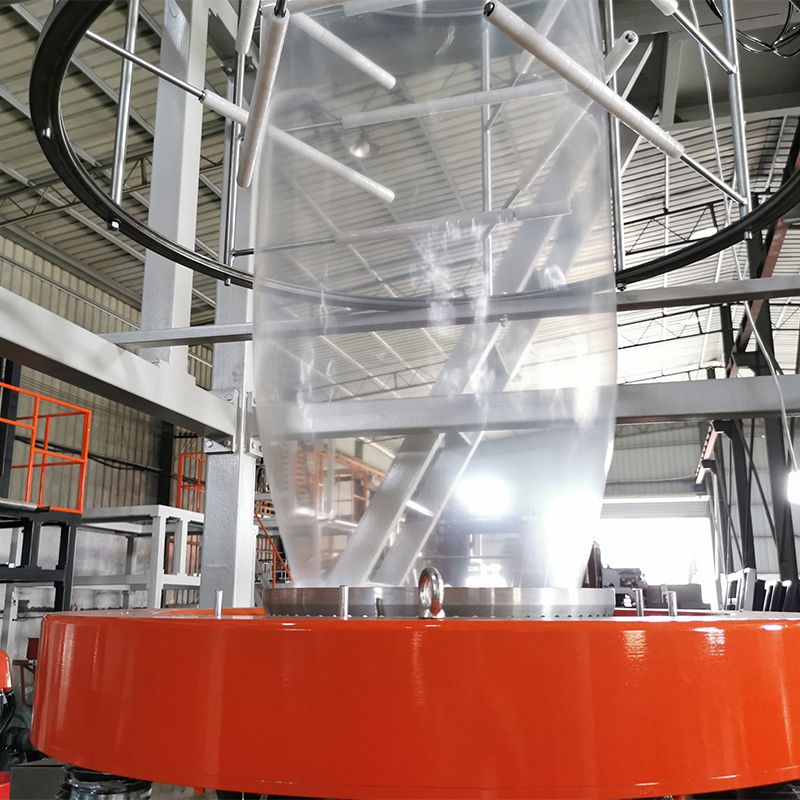

Two Layer Blown Film Machine

This two-layer blown film machine is a versatile tool for producing plastic films made of low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low density polyethylene (LLDPE). It is widely used for packaging liquids, printing materials, exporting products and industrial product packaging.

Technical Parameters

| Model | SJ-55*2/RG1200 | SJ-65*2/RG1500 | SJ-65*2/RG2000 |

| Screw diameter (mm) | 55/55 | 55/65 | 70/65 |

| Screw L/D ratio | 30:1 | 30:1 | 30:1 |

| Screw speed (r/min) | 110 | 110 | 110 |

| Capacity (kg/h) | 110 | 140 | 160 |

| Power of main motor (kW) | 18.5/18.5 | 18.5/30 | 30/37 |

| Diameter of die (mm) | 300 | 450 | 550 |

| Thickness of film (mm) | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 |

| Max. folding width of film (mm) | 1200 | 1500 | 2000 |

| Total power (kW) | 65 | 85 | 95 |

| Weight (kg) | 4500 | 6000 | 6500 |

| Dimensions (L*W*H, m) | 4.6×3.5×6 | 5.2×4×7.5 | 5.5×4.5×10 |

Features

- Double-layer co-extrusion complex films can significantly extend the shelf-life of products which are used in liquid packaging.

- Both barrels and screws of two extruders are constructed from high-grade alloy steel. The manufacturing process includes nitrating and precision finishing for improved hardness and resistance to corrosion.

- The double-layer co-extrusion rotary die of the die-head is designed to produce the greatest accuracy in thickness of the film.

- Equipped with a flat work table and a bubble cage, this accessorial equipment allows for easy operation.

- The winding unit consists of two rewinders and a double cutter. Employing a torque motor as its drive, the unit is capable of maintaining optimum tension and can smoothly and easily rewind a full roll.

Main Components

- Screw (Taiwan deign)

1. Material: 38 CrMoALA

2. Material elemental analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3. Hardness of tempering: HB260-290

4. Depth of nitriding treatment: 0.4-0.7 mm

5. Hardness of surface: HV900-1050

6. Roughness of surface: 0.32 Ra

7. Linearity of screw: 0.015 mm/m

8. Bimetal screw: designed with a layer of tungsten carbide applied to the thread

9. Hardness of bimetal layer: HRC 58-62

10. Depth of bimetal layer: 2-3 mm

11. Bimetal layer elements: Fe, Ni, B, C, Cu, etc. - Main Motor (Siemens)

1. Speed: 1400 rpm

2. Motor power: 380V, 3-Phase, can be adjusted as needed

3. Service life: more than 10 years. - Gearbox

1. Functions: reduces speed of transmission

2. Speed rate: 10:1

3. High strength hard gearbox boasting service life

4. Transferring requires lubrication oil

5. Low noise and longer service life - Heater (ceramic heater)

1. Ceramic heater heats up faster than stainless-steel alternatives

2. Its lifespan is no less than 5 years

3. t can better retain heat, resulting in lower power consumption

4. Made from high-quality ceramic and heating wire - Die Head (Taiwan design)

1. Made from #45 steel, providing robust performance

2. Surface treatment is employed to increase the transparency of films

3. The size of die heads is larger than normal, resulting in increased efficiency and productivity - Fast Screen Changer

1. Ensure that workers are employed efficiently

2. Minimize the risk of material leak

3. Easy to change the filters, saving time and human labor - Double Vent Air Ring

1. Using two lips instead of one can cool the film more quickly, thereby increasing the machine's output

2. LG inverter, Omron temperature controller box

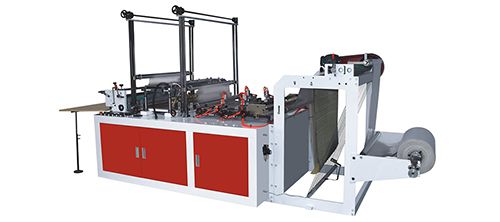

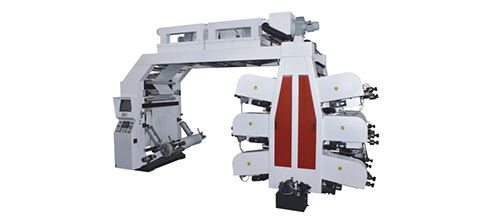

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch