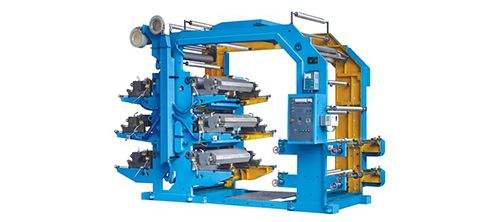

High Speed Blown Film Machine

(with Single Rewinder)

The screw and barrel of this high speed blown film machine are exceptionally durable due to the usage of 38 CrMoALA materials and three-day nitriding treatment. The resulting hardness is far superior to the norm so it will possess a longer lifespan.

This blown film machine has a single rewinder and a fixed die head, designed for use with HDPE, LDPE, and LLDPE materials. It is particularly tailored to processing HDPE materials.

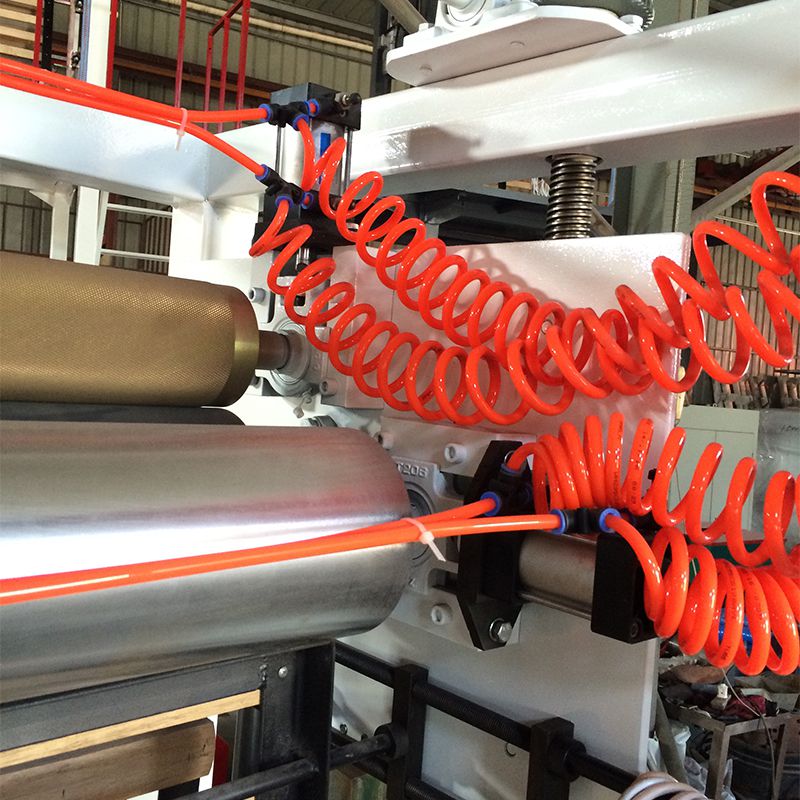

The embossing roller, paired with air control for the traction roller, makes this high speed blown film machine easy to use for factory workers. It is especially suitable for producing shopping bags in a new factory.

Technical Parameters

| Model | SJ-50/MB600 | SJ-55/MB800 | SJ-60/MB1000 | SJ-65/MB1200 |

| Screw diameter (mm) | Ø50 | Ø55 | Ø60 | Ø65 |

| Screw L/D ratio | 28:1 | 28:1 | 28:1 | 28:1 |

| Film width (mm) | 200-600 | 200-800 | 400-1000 | 600-1200 |

| Film thickness (mm) | 0.006-0.10 | 0.006-0.10 | 0.006-0.10 | 0.006-0.10 |

| Max. extrusion capacity (kg/h) | 40 | 45 | 55 | 60 |

| Die size (mm) | Ø60/100 | Ø80/150 | Ø100/200 | Ø120/250 |

| Power of cooling cylinder (kW) | 0.25 | 0.25X1 | 0.25X2 | 0.25X2 |

| Power of driving motor (kW) | 11 | 15 | 18.5 | 22 |

| Total power (kW) | 28 | 36 | 42 | 48 |

| Cover dimension (m) | 5.0*2.1*3.8 | 5.0*2.3*4 | 5.5*3.3*4.2 | 5.8*3.6*4.5 |

| Weight (kg) | 1800 | 2000 | 2300 | 2600 |

Main Components

- Screw

1. Material: 38 CrMoALA

2. Material elemental analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3 .Hardness of tempering: HB260-290

4. Depth of nitriding treatment: 0.4-0.7 mm

5. Hardness of surface: HV900-1050

6. Roughness of surface: 0.32 Ra

7. Linearity of screw: 0.015 mm/m - Main Motor

1. Chaoyue brand, CE standard certificated

2. 1400 rpm, 6-pole type, providing stronger power. - Gearbox

1. High strength hard gearbox boasting service life of more than 10 years

2. Oil of a particular grade with a designated mark that is used to ensure the smooth functioning of bearings. - Heater

1. This stainless heater has a long lifespan of over 5 years.

2. The E type thermal couple is used to measure the temperature of the barrel. - Fixed Die Head

1. HDPE and LDPE die head available

2. The head of the die features a nitriding treatment, which provides a very smooth interior surface. Polishing offers an additional smoothness to the die. - Air Ring

1. This single lip air ring is constructed from aluminum and has six air inlets for a reliable and efficient performance.

2. A high-speed blower is employed to quickly cool the film. - Electric Parts

1. KEQANG temperature controllers have an estimated lifetime of more than 10 years

2. CHINT contact providing best quality made in China. - Eletric Controller Box and Inverter

1. Shenou Brand Inverters boast an impressive ten-year life, meeting CE standards.

2. CHINT, one of the leading suppliers of switches and buttons in China

3. For improved speed regulation stability and electricity savings of up to 30%, the main motor has been outfitted with frequency control of motor speed. Additionally, the take-up motor has been adapted with a frequency inverter. - Gusset Part (with lifting system) Gusset part adopts Taiwan design, easy to adjust

- Embossing Roller

1. The default dot spacing designed to be 2mm, which can be customized to fit your needs.

2. Air cylinder control makes operation of this system simple and requires no manual labor. - Single Rewinder

1. The rewinder utilizes either torque motor-enabled center rewinding or friction rewinding with pressure to operate it.

2. Rewinding is effortless and seamless, as is rolls changing .

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs. In addition, we also supply other plastic processing machines including plastic film machines, plastic printing machines and plastic recycling machines to meet your diverse production demands. With years of engagement in the plastic industry, we pride ourselves in our expertise and ability to design and manufacture plastic film and bag making machines.

Get in Touch