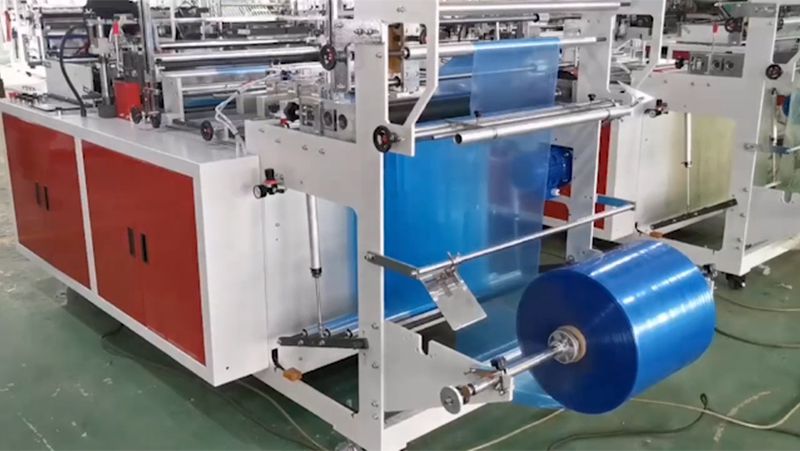

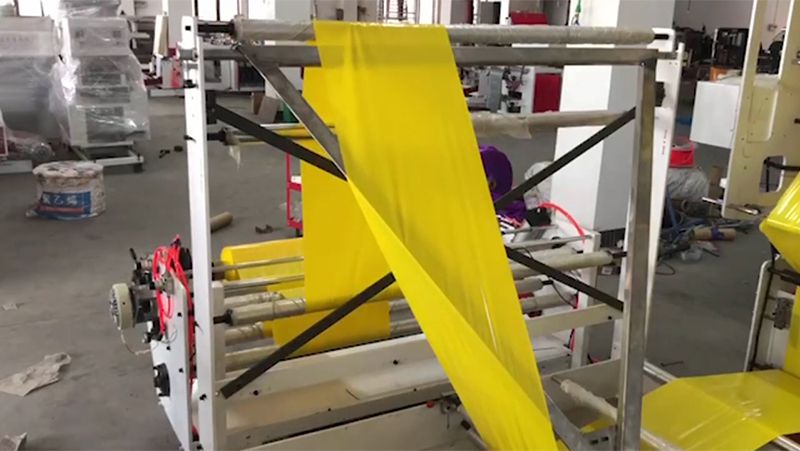

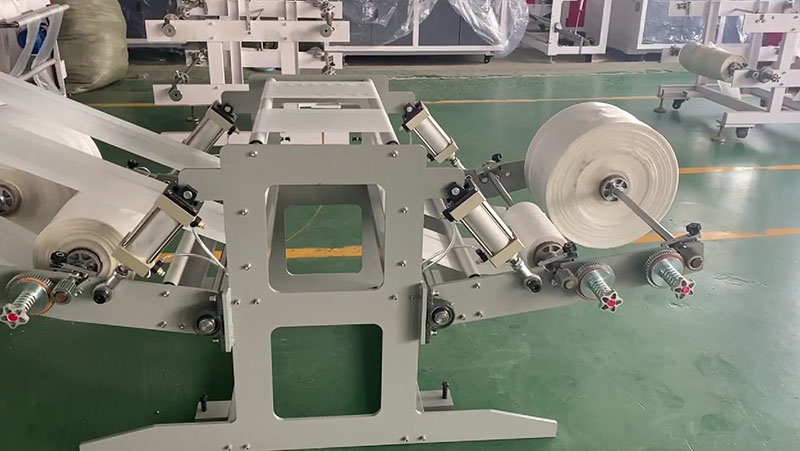

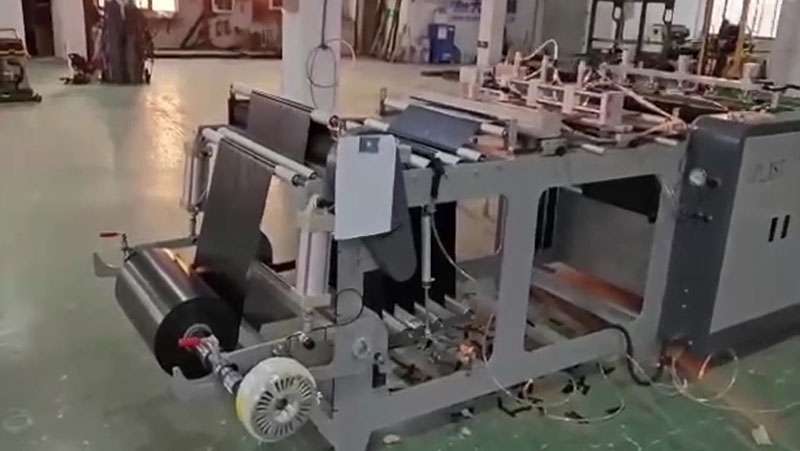

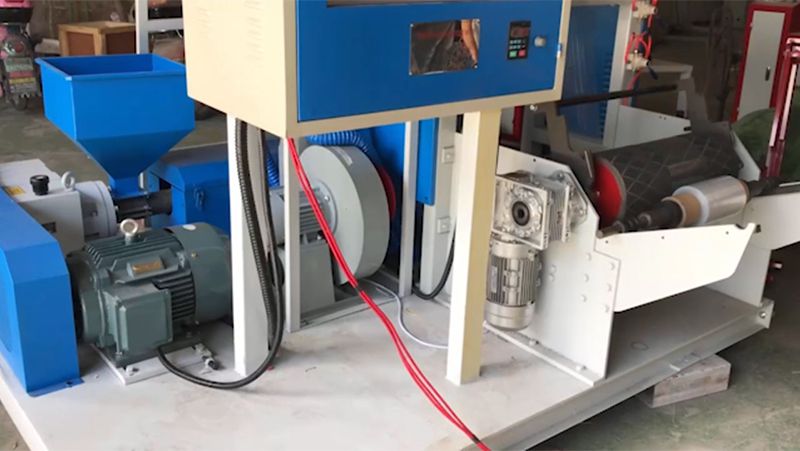

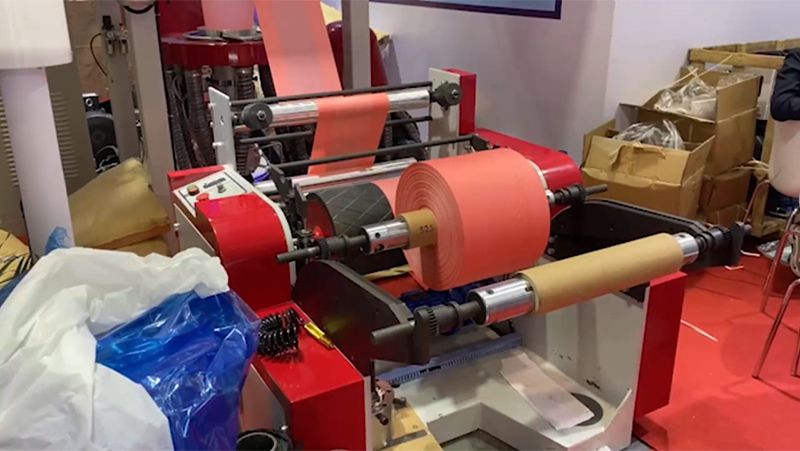

Mini Type Blown Film Machine

The mini type blown film machine’s screw and barrel are produced from 38 CrMoALA, while undergoing a three-day nitriding process that provides a higher level of strength and endurance, thereby substantially increasing the machine's overall lifespan.

This film blowing machine design is widely liked due to its simplicity. All components are pre-assembled onto a single steel base, eliminating the need for installation by workers. The only task left is connecting the power and air wires, making it quite straightforward.

Get in Touch