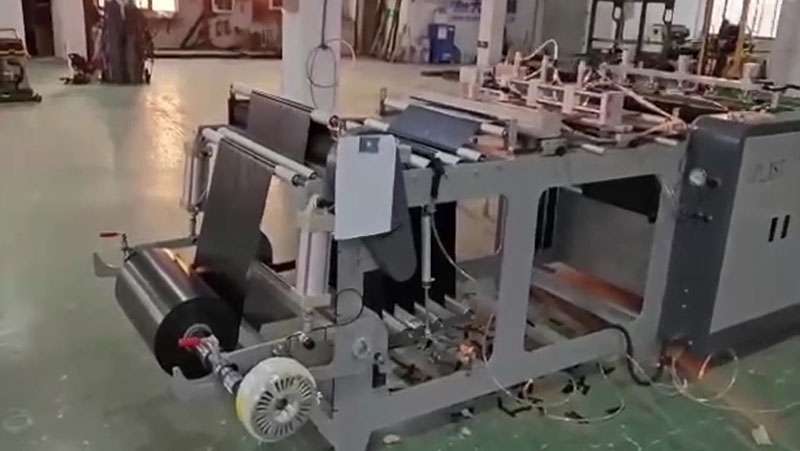

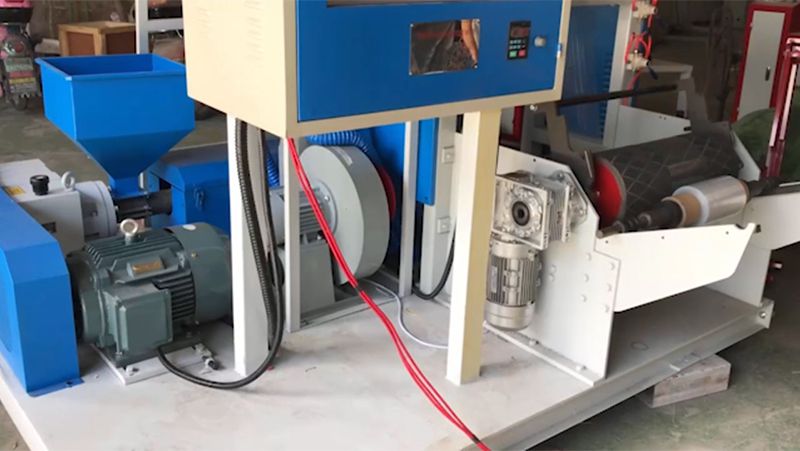

ABA Three Layer Blown Film Machine (Taiwan Design)

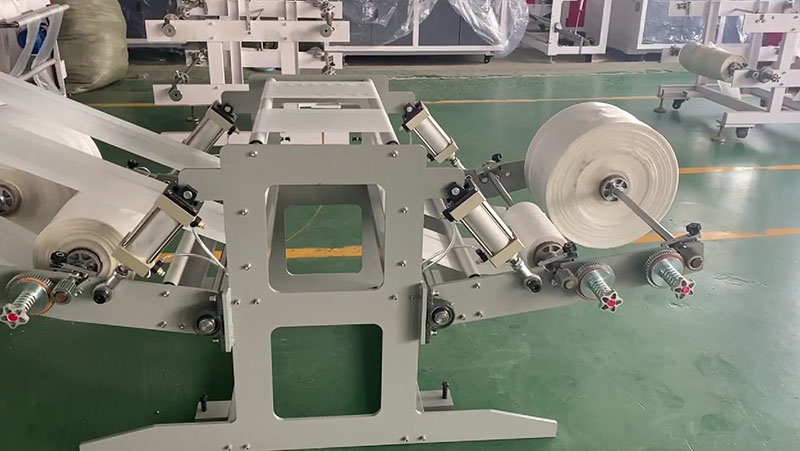

In this ABA three layer blown film machine, bi-metal alloy steel which contains 15% Tungsten carbide makes the barrel and screw particularly robust. This hardness ensures that they have a longer life expectancy by no less than 5 years.

Taiwanese engineering is behind the design of the screw, particularly the feeding and mixing parts. These components have substantially increased the productivity of the machine and the quality of the film.

Get in Touch